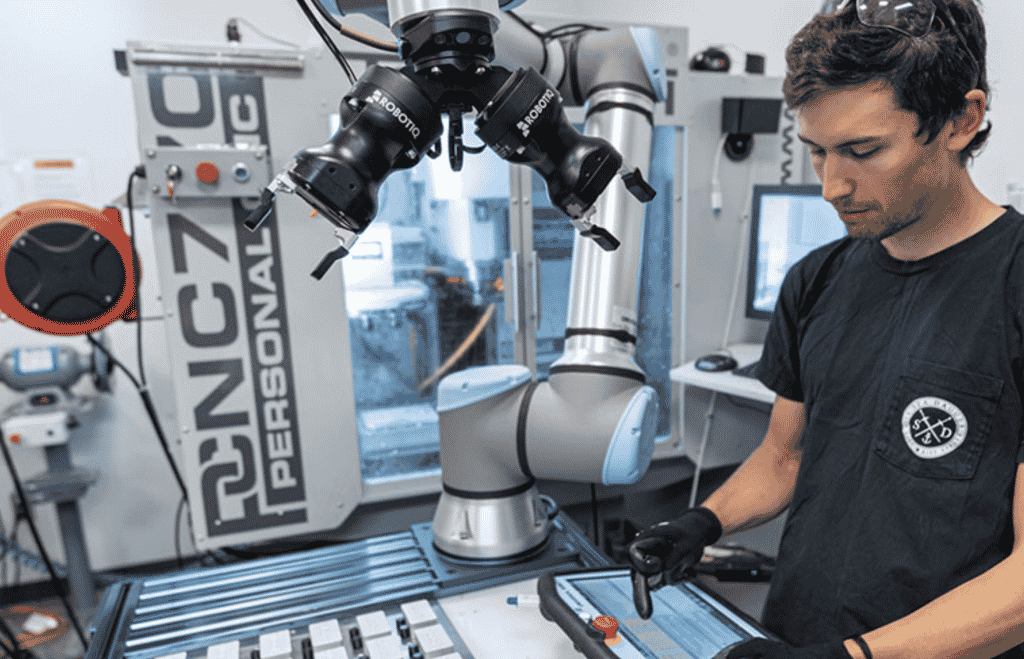

Robots are becoming widely used in the modern industries due to their efficiency, speed, and precision. Cobots, or collaborative robots are industrial robots that perform tasks automatically without human intervention. They are among the most popular types of industrial robots today, thanks to their ability to perform tasks that would otherwise be too dangerous or complex for human workers. The robotic arm is programmed to move around a certain area, picking up and putting down materials.

This cobot guide will explain the features, advantages, and applications of collaborative robots. So let’s get started

What Exactly Are Cobots?

A cobot is an autonomous mobile machine that can move around your factory floor and perform repetitive tasks such as welding, grinding, drilling, assembling, packaging, and more. Cobots have been used by manufacturers for decades because they allow you to automate certain tasks within your production process without having to hire additional staff.

Which Industries Can Benefit From Collaborative Robots?

1. Manufacturing

Manufacturing industries such as automotive, electronics, aerospace, and medical devices all rely heavily on robotics. It is estimated that there are currently over 2 million industrial robots operating in the manufacturing sector worldwide. This figure is expected to rise significantly in the coming years.

2. Warehousing

Warehouses are often filled with goods that must be stored safely until they reach their destination. This requires a lot of manpower and a high level of vigilance. However, robots can easily monitor each item and keep track of its location within the warehouse.

3. Agriculture

Agricultural equipment is another area where robots are widely used. These equipment include tractors, harvesters, sprayers, and other tools. Cobot applications can control the machines and make sure that they operate efficiently. They can also collect data and transmit information back to the operator.

4. Construction

Construction sites are dangerous places to work. There are lots of moving parts and heavy machinery. These factors mean that workers face an increased risk of injury or death. Robots can take care of all the physical aspects of building projects. They can even build structures without any human input whatsoever.

5. Service Industries

Service industries like restaurants, hotels, retail stores, and banks are among the fastest-growing sectors for robot adoption. This is largely because robots can perform mundane tasks that would otherwise require human labor. For example, robots can clean hotel rooms, stock shelves, and check guests into hotels.

Features of Collaborative Robots

1. Self-Guiding Technology

One of the main reasons why cobots are so popular is because they feature self-guided technology. This means that cobots do not require any manual guidance from humans while performing their tasks. Instead, they navigate themselves through your factory using sensors on their body and arms.

2. Safety Features

Another reason why cobots are so useful is that they come with built-in safety mechanisms. These mechanisms include collision avoidance systems and emergency stop buttons. The features aid in ensuring that your employees’ safety is always prioritized while still maintaining a high level of accuracy.

3. Multiple Joints

Cobots feature multiple jointed arms. This allows them to perform tasks that are difficult for traditional single-arm robots. One example of this is when cobots weld two pieces of metal together.

4. Integrated Vision System

Some cobot models come equipped with an integrated vision system. This enables them to see where they are moving at all times. It also helps them avoid obstacles and other objects on the factory floor.

Advantages of Cobots

A major advantage of using robots in factories is that they can complete a wide range of tasks that would take hours for humans. Robots generally perform these tasks faster and with less effort than humans. Unlike humans, robots don’t get tired, sore, stressed out, or sick. Here are 5 other advantages of using cobots.

1. Reduced Human Error

Humans make mistakes due to fatigue, stress, or illness. But robots never tire, get ill, or make mistakes. This reduces the risk of accidents happening and increases overall efficiency and productivity. The robot will perform tasks automatically without needing any intervention from humans. They can work around the clock without worrying about being interrupted by tired employees or distracted colleagues. They will not only save time but also ensure the safety of the workers.

2. Increased Output

Robots have been proven to increase production levels. This is mainly because they reduce the need for constant supervision. When compared to human operators, robots produce more outputs per hour. You can only hire fewer people to do the same amount of work as before. It also means that you can save money by reducing the number of staff needed to run a business.

3. Improved Quality

When compared to manual labor, robots produce better results. The repetitive nature of robotic tasks improves the quality of the end product. Recent research also shows that robots are more efficient than humans at performing certain types of work. They use advanced sensors and software to detect flaws and defects in products. This allows them to identify problems early and eliminate them before they become costly issues.

4. Cost-effective

Robots are much cheaper than hiring human labor. Even though they may seem expensive initially, they pay off over time because they help cut costs and improve efficiency. In addition, they don’t require extensive training and can be used immediately after purchase. This can save the business considerable amounts of money.

5. Improved Productivity

The most obvious benefit of using robots is that they allow you to achieve higher levels of productivity. In some cases, it has been shown that robots can replace up to 50% of the workforce. When combined with computerized systems, robots can automate many processes and free up your employees to focus on more complex jobs.

Bottom Line

It seems clear that robots will play a major role in our future. As technology continues to advance, we will see more and more robots enter the workplace. This means that companies should consider investing in robots to streamline operations and increase profits. When it comes to collaborative robots, (company name) offers a wide range of solutions that are tailor-made to meet specific needs. (Company name)’s cobots are designed to help improve safety and efficiency at your facility. They are easy to use and don’t require extensive programming. Get in touch with us today for more information about how our cobots can benefit your business.